ZS Zylinderbau & Service GmbH

Are you looking for a partner for special hydraulic cylinders and machines? ZS Zylinderbau & Service GmbH is what you need.

We move with great power!

We engineer and manufacture special hydraulic cylinders and hydraulically operated special machines and devices. We are also happy to offer you a package solution including power unit and control system.

Our focus is on large cylinders with piston diameters of over 200mm up to 1200mm. However, we are also the right partner for special designs, materials, coatings and equipment in smaller dimensions.

Thanks to our experience and operating equipment we are also ideally positioned for the professional repair of all types of hydraulic cylinders.

Application examples:

- Vertical mills, roller mills and roller presses

- Scrap presses and scrap shears

- Forming technology and bending machines

- Stamping and straightening presses

- Mining and steelworks technology

- Roll and tube bending machines

- Pipe testing equipment

- Filter presses

- Test benches

- Steel hydraulics construction

- Weir flaps and sluice gates

- Bascule bridges

- Ship locks

History

The roots of ZS lie in the repair and manufacture of hydraulic cylinders and the development of manipulators for coal mining. They date back to the 70s.

Since the decline of mining in Germany, we have been concentrating on new fields of application in general mechanical engineering, press, plant and steel hydraulics construction.

Important milestones in ZS history are:

2020

The ZS Zylinder-Service GmbH becomes the ZS Zylinderbau & Service GmbH.

2015

A new office wing will be established in the “old hall”.

2013

Extension of the first “new” hall to 80m. Total area now approx. 2,000m²

2013

Lutz Mohrmann joins the management board as 2nd managing director.

2011

Construction of the assembly hall 580m² with 20t bridge crane

2006

First new hall building in Stupno. 600m² / 10t bridge crane

1999

Foundation of ZS Zylinder-Service GmbH in Xanten and the subsidiary ZS Bohemia s.r.o. with production start in Stupno (CZ) by Michael Mohrmann.

1996

Concentrated orientation towards new markets with design and administration in Xanten (D) / production until 1999 with cooperation partners in the Czech Republic.

1980

Michael Mohrmann takes over NLW Fördertechnik GmbH at the later ZS company headquarters. Here, mainly plants for coal mining are repaired, overhauled and improved. The experience gained from the repair of approx. 50,000 hydraulic cylinders also provides an important basis for the redesign of cylinders later by ZS.

Production and repair of over 50,000 hydraulic cylinders

Products

Special hydraulic cylinders

When standard cylinders are no longer sufficient, that is where we start.

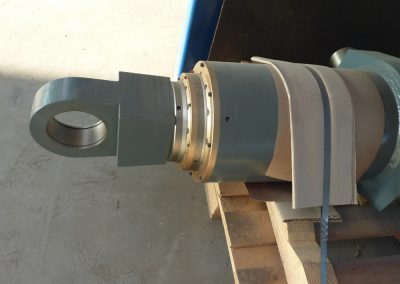

Our speciality are large cylinders with piston diameters from 200mm to 1200mm and lengths up to 14m. For special designs or materials, however, we are also the right contact partner for smaller dimensions. Our design engineers will find a solution for every special application.

Our spectrum covers among other things:

- Drive and pulling cylinders

- Single and double acting cylinders (piston ø200-1400mm)

- Telescopic cylinders (e.g. 5 steps)

- Actuator cylinders and servo motors (e.g. guide vane adjustment in hydroelectric power plants)

- Rapid-motion cylinders (e.g. for straightening press (fast travel without load))

- Flat cylinders (shortest installation space e.g. 370mm with piston ø900mm)

- Plunger cylinders

- Differential cylinders

- Press and pressure cylinders (straightening presses, filter presses, forging presses, etc.)

- Test cylinders

- Control cylinders

- Regulating cylinders

- Weir flap cylinders (also standing in water)

- Sluice gate cylinders (e.g. inlet Sluice gate hydroelectric power station, 12m stroke)

- Lifting cylinders

- Pressure intensifier (operated with oil and water)

- Pressure accumulators

…and of course, any kind of new construction for your special application!

As our machinery is equipped for the production of large cylinders, we can also realise fast and cost-effective production based on your existing design.

Two cylinders each for operating a 70t inlet contactor in a hydroelectric power plant. With 12.5m stroke and integrated displacement measuring system.

Two cylinders each for operating a 70t inlet contactor in a hydroelectric power plant. With 12.5m stroke and integrated displacement measuring system.

Servo motors for adjusting guide vanes with millimetre precision

Servo motors for adjusting guide vanes with millimetre precision

Straightening cylinder with rapid traverse and anti-twist device

Straightening cylinder with rapid traverse and anti-twist device

Pendulum piston cylinder: diameter = 8 x stroke. Guide inside, seal outside

Pendulum piston cylinder: diameter = 8 x stroke. Guide inside, seal outside

Counter cylinder: holds 4600t when large pipes are squeezed

Counter cylinder: holds 4600t when large pipes are squeezed

Cylinder with lateral guide for controlling large radial forces

Cylinder with lateral guide for controlling large radial forces

Weir flap cylinder for regulating the water level – in summer

Weir flap cylinder for regulating the water level – in summer

Weir flap cylinder for regulating the water level – in winter

Weir flap cylinder for regulating the water level – in winter

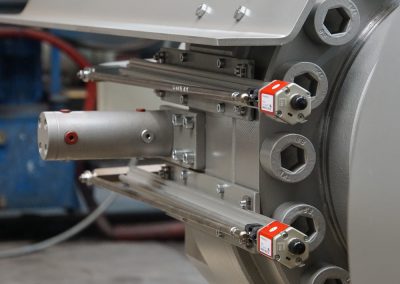

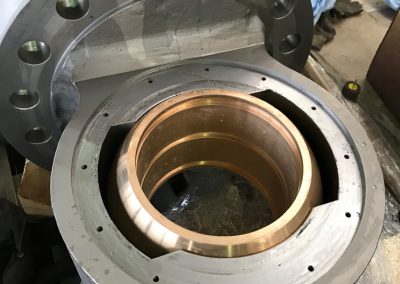

Spherical plain bearing lock with stainless steel rings and sealing

Spherical plain bearing lock with stainless steel rings and sealing

Stamped screws with 3.2 certificate according to EN 10204

Stamped screws with 3.2 certificate according to EN 10204

3-fold redundant displacement measuring system (magnetostrictive)

3-fold redundant displacement measuring system (magnetostrictive)

Equipment variants

We manufacture special cylinders in various designs and equipment!

Since the field of application of hydraulic cylinders is very broad, they have to meet different requirements: stability against lateral forces, speed, temperatures, corrosion protection, material usage and sensor technology.

These requirements can often only be met by special equipment. We are also a competent partner in this area.

Examples of equipment variants:

- Adapted sealing systems and guides

- Massive ice scrapers

- Rapid traverse (small “cylinder in cylinder” for fast movements with low load)

- End cushioning, adjustable or fixed

- Special coatings and corrosion resistant materials

- Low temperature steels for use in the Arctic

- Suction valves

- Limit switches, sensors and displacement measuring systems

Equipment variants

We manufacture special cylinders in various designs and equipment!

Since the field of application of hydraulic cylinders is very broad, they have to meet different requirements: stability against lateral forces, speed, temperatures, corrosion protection, material usage and sensor technology.

These requirements can often only be met by special equipment. We are also a competent partner in this area.

Examples of equipment variants:

- Adapted sealing systems and guides

- Massive ice scrapers

- Rapid traverse (small “cylinder in cylinder” for fast movements with low load)

- End cushioning, adjustable or fixed

- Special coatings and corrosion resistant materials

- Low temperature steels for use in the Arctic

- Suction valves

- Limit switches, sensors and displacement measuring systems

Spherical plain bearing lock with stainless steel rings and sealing

Spherical plain bearing lock with stainless steel rings and sealing

Stamped screws with 3.2 certificate according to EN 10204

Stamped screws with 3.2 certificate according to EN 10204

3-fold redundant displacement measuring system (magnetostrictive)

3-fold redundant displacement measuring system (magnetostrictive)

Complete hydraulic systems and hydraulic devices / machines

Every hydraulic cylinder can only develop its power when one power unit builds up the required pressure. To ensure that the movement takes place at the right moment, it must also be controlled.

The experts at ZS Zylinderbau & Service GmbH will take care of your task with all the necessary elements. We offer you the complete hydraulic system with cylinder, power unit and control system from one source.

On request, we go one step further and design, build and supply you with complete hydraulically driven devices which are integrated into your machines and systems.

Examples:

- Test rig for tensile testing of components for offshore plants

- Device for calibrating / expanding large diameter pipes

- Device for swinging out worn grinding rolls in coal mills

- Device for changing rolls in a billet rolling mill

- Lift tables integrated into the production chain

- Press for the manufacture of grinding wheels

- Installation device for mobile 30m high gas flare (transport on normal trucks possible)

- System for manufacturing clad pipes (drawing a thin stainless steel pipe into a carbon steel pipe as a cheaper alternative to solid stainless steel pipe for corrosive media)

Concrete pipe turning unit for safe tilting of large concrete pipes by 90°.

Concrete pipe turning unit for safe tilting of large concrete pipes by 90°.

Grinding wheel press – completely manufactured by ZS, incl. lifting tables for loading

Grinding wheel press – completely manufactured by ZS, incl. lifting tables for loading

Maintenance and repair

We maintain and repair quickly and reliably!

The service of ZS Zylinderbau & Service GmbH can rely on the experience of more than 50,000 built and repaired cylinders mainly from the mining industry.

We know how expensive a machine downtime can be and are prepared to repair the cylinders as quickly and efficiently as possible. After dismantling the cylinders to be repaired, we will then determine, in consultation with you, whether damaged components should be replaced by new parts or can be reconditioned quickly and cost-effectively.

Having our own desgin and manufacturing, we can also identify possible improvements and implement them during the repair work if necessary.

For example:

- Conversion to more modern sealing systems

- Modified guides

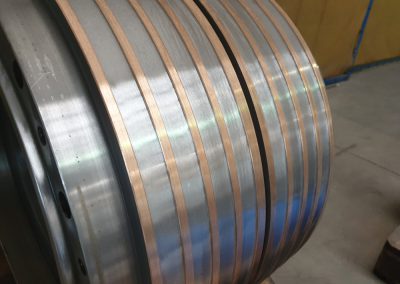

- Overlay welding, e.g. with bronze for gap reduction or with stainless steel as corrosion protection at critical points

- Modified piston rod coating, e.g. stainless-steel weld-on, ceramic coatings, tungsten carbide, – laser clad coating, etc.

- Reinforcement of individual components

- Also of course, new production of individual parts

After disassembly, customers always receive a cost estimate for the planned measures, as well as a list of the individual repair work and used spare parts and the test reports after reassembly.

As you can see, even with your existing cylinder you are at the right address with us.

Maintenance and repair

We maintain and repair quickly and reliably!

The service of ZS Zylinderbau & Service GmbH can rely on the experience of more than 50,000 built and repaired cylinders mainly from the mining industry.

We know how expensive a machine downtime can be and are prepared to repair the cylinders as quickly and efficiently as possible. After dismantling the cylinders to be repaired, we will then determine, in consultation with you, whether damaged components should be replaced by new parts or can be reconditioned quickly and cost-effectively.

Having our own desgin and manufacturing, we can also identify possible improvements and implement them during the repair work if necessary.

For example:

- Conversion to more modern sealing systems

- Modified guides

- Overlay welding, e.g. with bronze for gap reduction or with stainless steel as corrosion protection at critical points

- Modified piston rod coating, e.g. stainless-steel weld-on, ceramic coatings, tungsten carbide, – laser clad coating, etc.

- Reinforcement of individual components

- Also of course, new production of individual parts

After disassembly, customers always receive a cost estimate for the planned measures, as well as a list of the individual repair work and used spare parts and the test reports after reassembly.

As you can see, even with your existing cylinder you are at the right address with us.

Production

Production takes place at ZS – Bohemia s.r.o. in the Czech Republic near Pilsen. Complete mechanical processing as well as assembly and testing are carried out at this location. For this purpose, we have at our disposal the following conventional and CNC machines on an area of approx. 2000m²:

- Lathes for diameters up to 1600mm and lengths up to 14000mm

- Boring mills for the processing of parts up to 12t piece weight

- Cylindrical grinding machines and fixtures for diameters up to 730mm and lengths up to 8000mm

- Honing benches for diameters up to 1000mm and lengths up to 8000mm

- Semi-automatic welding fixtures for MAG and UP welding processes

- Bridge cranes up to 20t

- Test bench for pressure testing up to 700bar

- Special devices for handling, assembly and testing, tailored to our needs.

We are working together with longtime reliable partners for the coating of piston rods (chrome, ceramic, tungsten carbide or laser clad process) as well as for further processing steps outside our capacities.

ZS Bohemia s.r.o., like ZS Zylinderbau & Service GmbH, has a certified quality management system according to ISO 9001.

For the execution of welding work, we have certification according to ISO 3834 and EN 1090.

Vertical mounting – for optimal alignment of the parts during assembly. Pit depth: 4.5m

Vertical mounting – for optimal alignment of the parts during assembly. Pit depth: 4.5m

DOWNLOADs

Contact

ZS Zylinder Service GmbH

Bruchweg 15

46509 Xanten-Birten

Deutschland

Fon +49 (0) 2801 71650-0

Fax +49 (0) 2801 90740

Construction & administration at the location in Xanten, Germany

ZS Zylinderbau & Service GmbH

Bruchweg 15

46509 Xanten-Birten

Germany

Fon +49 (0) 2801 71650-0

Fax +49 (0) 2801 90740

info[at]zs-zylinder.de

ZS Bohemia s.r.o.

Stupno 153

CZ-338 24 Břasy

Fon +420 371 793 046

Fax +420 371 793 048

Production at the site in Stupno, Czech Republic

ZS Bohemia s.r.o.

Stupno 153

CZ-338 24 Břasy

Fon +420 371 793 046

Fax +420 371 793 048

zsbohemia[at]zsbohemia.cz

Personal data that you send us via the above contact form will only be used to respond to your request and for the technical administration associated with this process. The data will not be passed on to third parties.

You have the right to revoke your consent to contact us at any time with effect for the future. In this case the personal data stored about you will be deleted immediately. After processing your request, the data will also be deleted immediately.

Further information on data protection and the handling of personal data can be found in our privacy policy.

Contact person

ZS Zylinderbau & Service GmbH, Germany

Management /

Technical Manager / Sales Management

Lutz Mohrmann, Dipl.-Ing.

+49 (0) 2801 71650-17

lutz.mohrmann[at]zs-zylinder.de

Purchasing management

Andreas Sobiech

+49 (0) 2801 71650-12

andreas.sobiech[at]zs-zylinder.de

Management

Michael Mohrmann, Dipl.-Ing./Dipl.-Wirt.-Ing.

+49 (0) 2801 71650-11

michael.mohrmann[at]zs-zylinder.de

Accounting

Nicola Thiel

+49 (0) 2801 71650-23

nicola.thiel[at]zs-zylinder.de

Workshop / Repairs

Jörg Rosowski

+49 (0) 2801 71650-14

joerg.rosowski[at]zs-zylinder.de

Distribution France

Kevin Legrand

kevin.legrand[at]zs-zylinder.de

Head of construction

Andreas Klother, Dipl.-Ing.

+49 (0) 2801 71650-21

andreas.klother[at]zs-zylinder.de

ZS Bohemia s.r.o, Czech Republic

Head office

+420 371 793 046

zsbohemia[at]zsbohemia.cz